- HOME

- Applications

- EMI Solutions

Meeting EMC requirements is critical, and TDK-Lambda Power Solutions and EMI filters provide a reliable solution.

Reliable operation, maximum availability without downtime, satisfied users, and no complaints—that is the goal of every device manufacturer and developer. One of the prerequisites for achieving this is meeting the requirements for electromagnetic compatibility (EMC). EMC ensures the trouble-free operation of devices and systems working alongside and with each other in an increasingly challenging electromagnetic environment as the density of applications increases.

Understanding EMI, EMS and EMC

Electromagnetic Interference (EMI) refers to the disruptive electromagnetic energy emitted by a device. Electromagnetic Susceptibility (EMS) is the ability of a device to withstand external electromagnetic disturbances without degradation in performance. Electromagnetic Compatibility (EMC) represents the overall compliance with EMI and EMS requirements. Simply put, EMI + EMS = EMC.

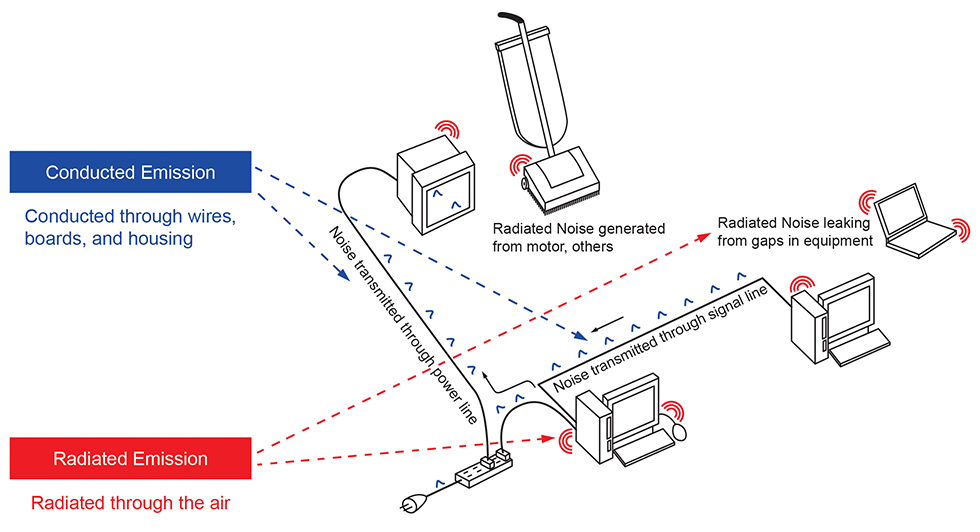

Radiated vs. Conducted: Electromagnetic emissions can be either radiated, meaning they propagate through air or space, or conducted, meaning they travel along conductive materials like wires or cables. Each type of emission requires specific mitigation strategies to prevent interference.

Noise Emission Types

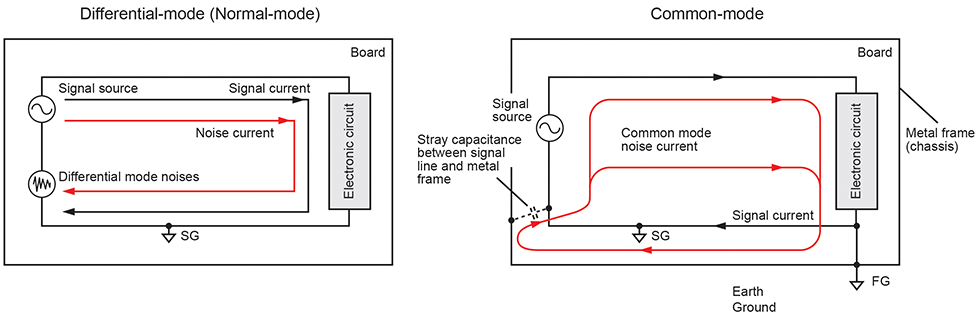

Electromagnetic Interference (EMI) created in switch-mode power supplies comes in two types: Differential Mode noise and Common Mode noise. Differential Mode noise is generated in the power conversion process, whereas Common Mode noise is coupled through parasitic capacitance. EMI noise filters are mainly effective in reducing conducted emissions, which are up to 30MHz, and they can also help reduce radiated EMI.

Transmission Types of Noise

There are two levels of conducted EMI requirements: Class A and Class B. Compliance depends on the specific requirement. Class B has a higher level of attenuation and is more difficult to meet. All EMC standards are always applicable to the final equipment, and it is crucial to have good grounding and proper cable routing to minimize conducted EMI. For deeper explanations and to view our EMI brochure for solutions, see the links below.

Complying with EMC standards

Challenges

EMC compliance testing is one of the final stages in a project’s development. Choosing a "low-cost" solution can result in exceeding EMI limits or failing immunity surge testing. This can lead to schedule delays, the need for over-filtering the solution, and may require safety re-certification, resulting in increased costs.

Our Solutions

The R series of EMI filters offers a huge range of package styles, including DIN rail, current ratings and input voltages for wide range of applications. Our technical team is available to assist with selecting the best EMI filter for your application.

Reducing electrical noise and providing surge protection

Challenges

Understanding the type of electrical noise is crucial to avoid system malfunctions. There are three sources of electrical noise: internally generated noise, noise generated by nearby equipment, and noise caused by electrical storms.

Our Solutions

The R series of EMI filters includes a choice of ferrite, amorphous, and nanocrystalline soft magnetic core inductors. Amorphous core inductors offer higher saturation levels than ferrite and effectively suppress high pulse noise generated from external equipment. TDK’s amorphous core technology provides greater long-term reliability than semiconductor clamps, which can degrade after multiple line surges. For more information https://www.us.lambda.tdk.com/resources/blogs/20240627.html

Nanocrystalline cores have improved low frequency band (tens of kHz) attenuation and thermal stability find out more here https://www.us.lambda.tdk.com/resources/blogs/20240903.html

UL508A Safety Certification

Challenges

The UL508A 2020 revision added SCCR (Short Circuit Current Rating) requirements for EMI filters used in industrial control panels, machinery electrical panels, and some motor control panels. These are now required to comply with UL508A.

Our Solutions

EMC filters with SCCR ratings can shorten the time and cost for UL508A safety certification. TDK-Lambda offers EMI filters with safety-certified SCCR ratings. For more information, see [our blog].

https://www.us.lambda.tdk.com/resources/blogs/20240520.html

and our EMI filter brochure below for more details.

Medical EMI Filters

Challenges

Meeting EMC requirements in medical devices is especially crucial, as a malfunction can have dire consequences. These devices often operate in high-noise environments generated by MRI scanners or other equipment, particularly in home healthcare.

Global medical certifications such as UL/EN/IEC 60601-1 and CISPR 11 are designed to limit interference to protect patients.

Our Solutions

The R series of EMI filters offers medical EMI filters with low AC leakage currents, ideal for medical devices. . View our EMI filter brochure below for more details.

Global EMC Testing Capability

TDK-Lambda has a worldwide network of 3-meter anechoic EMC test chambers located in Japan, the UK, Israel, China, Singapore, and America. These chambers are used for internal EMC compliance testing of our products.

A benefit to our valued customers is that this global network of anechoic chamber testing facilities can be utilized to assist those who may be experiencing EMI compliance issues, directly supported by the design center of TDK-Lambda products. Our value is enhanced when our engineering team is seen as an extension of our customers' engineering teams. We are here to help you with EMC issues.

Why TDK-Lambda?

Associated Power Guy Resources

Complying with EMC Standards | Video | TDK-LambdaApplications and use of EMI Filters for Industrial and Medical Applications I Blogs I TDK-Lambda

Selecting a line filter to reduce input transients | Blogs | TDK-Lambda

How to select an EMI filter and how is EMI testing performed? | Blogs | TDK Lambda

Why are EMI/EMC filters needed? | Blogs | TDK Lambda

Does it matter how an EMC/EMI filter is wired to a power supply? | Blogs | TDK-Lambda

Short Circuit Current Rating (SCCR) and how does it apply to AC-DC Power Supplies and EMC/EMI filters? | Blogs | TDK-Lambda

Using nanocrystalline cores for EMI filtering | Blogs | TDK-Lambda

Reducing Switching Power Supply Radiated & Conducted EMI | Blogs | TDK-Lambda

Guide to EMC Standards for Power Supplies | Blogs | TDK-Lambda