- HOME

- Applications

- Avionics and Defense/COTS

Delivering reliable power solutions for mission critical applications from 10W to multi-kilowatt for the Avionics and Defense/COTS market.

Avionics and defense are among the most demanding applications. Very high-reliability expectations are frequently combined with a harsh environment and an aggressive approach regarding the size, weight and power profile.

Similar to other industries, the future in defense will be shaped by digitization, but with a focus on low-risk innovation with trusted partners. Closely aligned with the desire for innovation is the constant need by the defense industry for ongoing improvements in reducing the size, weight and power, plus cost (SWaP-C).

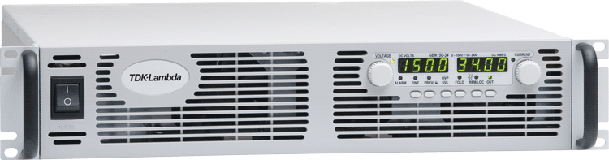

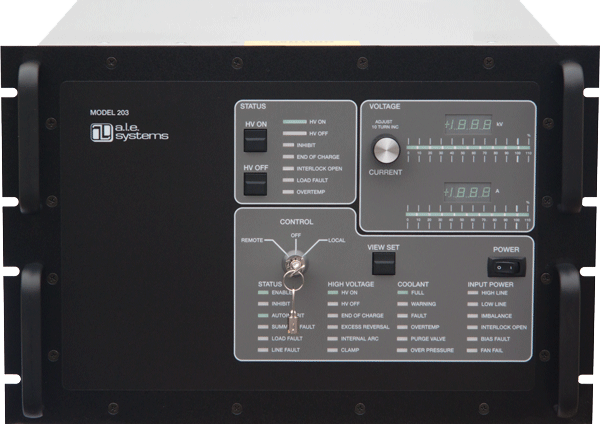

TDK-Lambda's Avionics and Defense/COTS power supplies are deployed in shipboard systems, ground vehicles, communications systems and other mission-critical land, sea and air applications. The power solutions are designed to reliably operate under the harsh environments that these applications require.

- Encapsulated and Ruggedized Bricks

- -40°C Operation

- Conformal coated PCBs

- Baseplate / Conduction Cooled

- Products designed to meet MIL-STD-461 EMC, MIL-STD-1275, MIL-STD-810 Shock/Vibration, MIL-STD-704, RTCA-DO-160

- Enhanced screening options

MIL-STD-810

Challenges

The MIL-COTS environmental testing requirements are tailored for the actual environment in which the equipment is expected to be deployed. For power supplies, this typically entails mechanical ruggedization considerations in order to meet the extreme shock and vibration exposures.

Our Solutions

We have Commercial Off-The-Shelf (COTS) solutions compliant to MIL-STD-810 and the capability to strengthen traditional COTS products to meet your MIL-STD-810 requirements.

MIL-STD-461

Challenges

MIL-STD-461 provides electromagnetic interference limits and test procedures for military equipment. Depending on the susceptibility and emissions criterion to be met, additional mitigation/filtering is often necessary. The extended low frequency range down to 10 kHz creates added complexity to the filtering design for the power solutions.

Without proper mitigation, interference effects in this low frequency range can impact critical defense equipment (e.g. low frequency acoustic/sensor systems).

Our Solutions

Our catalog of products include power solutions compliant to MIL-STD-461 and external filters to help meet these requirements.

Standard products can also be customized to meet your MIL-STD requirements with our Value Add Solutions & Capabilities.

MIL-STD-1275; 704/DEF-STD 61-5

Challenges

Input immunity standards for various line disturbances (e.g. input surge, transient, spike conditions) for military ground vehicles, aircraft and naval vessels. Requires proper design considerations for compliance and reliable operation of the power solutions when subjected to these input disturbances.

Our Solutions

In addition to our standard power supplies and DC-DC converters, we also offer cost effective filter modules/accessories to help in meeting your MIL-STD requirements.

RTCA DO-160

Challenges

Environmental Conditions and Test Procedures for Airborne equipment is covered by the DO-160 standard. Section 16 refers to power input, simulating conditions of aircraft power from before engine start (using auxiliary ground based power) to after landing, including emergencies. For power supplies, the extended operation during momentary power interruptions (200ms hold-up) is typically a nuisance to meet unless considered early in development.

Our Solutions

We also have accessories available to increase the hold-up time and meet your RTCA DO-160 requirements.How can I increase a power supply's hold-up time? Standard products can also be customized to meet your MIL-STD requirements with our Value Add Solutions & Capabilities.

Altitude & Extended Operating Temperatures

Challenges

Thermal management, power derating, creepage and clearance are among a few things that the power solution needs to take into account when operating at higher altitude.

Our Solutions

We offer convection or conduction cooled solutions and fully potted power modules with wide operating temperatures (-55 to +115°C) that suit these environments.