- HOME

- Products

- Value Add Solutions & Capabilities

Value is enhanced as we become an extension of your engineering team

Leverage our expertise early in your design cycle!

Why choose TDK-Lambda as your partner for Value Add Solutions?

- ✓Breadth of Standard products - over 6,000 models from 1.5W to 100kW

- ✓World class design and engineering support

- ✓Lower development risk with proven Standard solutions

- ✓Optimized supply chain with these High Level Assemblies

- ✓Increased productivity with these turnkey solutions

- ✓Global manufacturing and engineering teams for local support

- ✓Low cost manufacturing for reduced system cost

- ✓Faster time to market compared to full custom solutions

- ✓Reliable heart for your system

Trusted・Innovative・Reliable

TDK-Lambda's product catalog covers more than 6,000 standard models, which provides us with the largest selection of standard power platforms to leverage our Value Add Solutions & Capabilities. Any TDK-Lambda standard power supply may be used as a starting point of your modified standard or value add power solution, leveraging the strength of the proven reliability from the original standard product platform.

Knowledge is power, power is TDK-Lambda!

Mechanical/Electrical/Firmware Capabilities

- Filter design for specific ripple and noise standards

- Full Digital Monitoring and Control

- Design and Simulation Tools (3D modeling, thermal, stress and mass simulation)

- Firmware development

- Battery charging solutions

- Voltage adjustments

- Cable assemblies/custom interconnects

- Product ruggedization

- Advanced Topologies (Bridgeless Totem Pole PFC)

Safety, Compliance, Quality and Testing

- Safety Compliance Engineering/Full Turnkey Certification

- Expert knowledge of UL, TÜV, CSA, CE and CB schemes

- ISO9001, ISO14001 and ISO13485 certified facilities

- ITAR Compliance

- ITE, Industrial and Medical Safety/EMC Standards

- HALT, HASS and additional Environmental Testing

- 100% parametric DVT testing

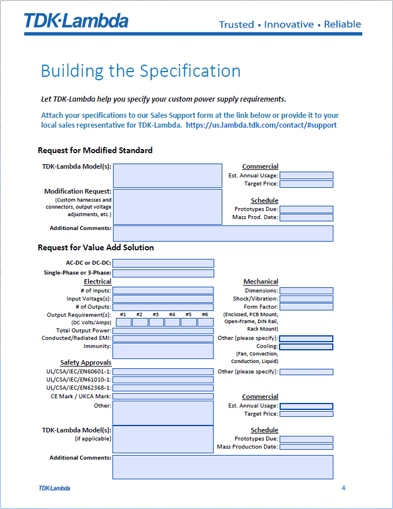

Overview of TDK-Lambda Value Add Solutions & Capabilities

click the image to see integration story

MIL-STD Communication System

DUV Lithography

Interactive Video Wall Display

Burn-In Testing

Water Purification System

Web Press Printer

Wafer Inspection System

MIL-STD Communication System

Distributed Antenna System

Broadcasting

Hybrid Electric Vehicle

Outdoor Display

Modified Standard300 Watt Single Output – Modified Connector

- Market Segment: Industrial

- Application: Postal Sorting System

- Standard Power Platform: SWS300-24 (AC/DC)

Key Features:

- Modified connectors to support ruggedized mounting connection

- Fully tested by TDK-Lambda to increase customer productivity

TDK-Lambda Value is enhanced

when our engineering team is seen as an extension of your engineering team for Power

Leverage our expertise early in the design cycle

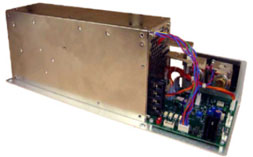

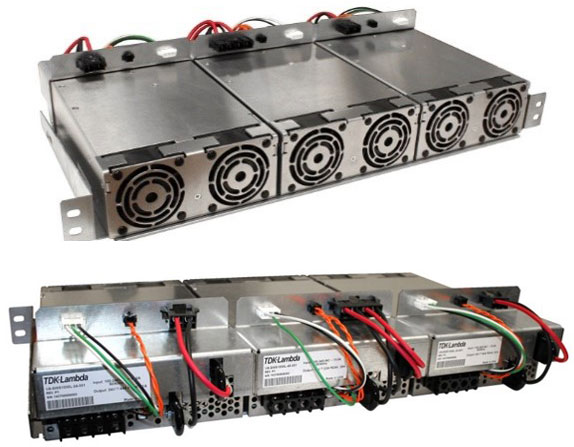

Value AddHigh Level Assembly for Increased Productivity

- Market Segment: Medical

- Application: Medical Diagnostic Imaging System

- Standard Power Platform: SWS1000L (AC/DC)

Key Features:

- Full turnkey solution to support rack mount application

- Fully tested by TDK-Lambda to increase customer productivity

- Extension to customer's Engineering team – management and support of requested design revisions

TDK-Lambda Value is enhanced

when our engineering team is seen as an extension of your engineering team for Power

Leverage our expertise early in the design cycle

Value Add1000 Watt Single Output Ruggedized Power Box

- Market Segment: Defense

- Application: Communication System

- Standard Power Platform: LZSA1000 (AC/DC)

Key Features:

- Include robust connectors and box

- Fully tested by TDK-Lambda to increase customer productivity

TDK-Lambda Value is enhanced

when our engineering team is seen as an extension of your engineering team for Power

Leverage our expertise early in the design cycle

Value Add3,000 Watt Turnkey Assembly with 3-phase Input

- Market Segment: Semi-Fab

- Application: Wafer Fabrication

- Standard Power Platform: TPS3000-48 (AC/DC)

Key Features:

- Provide turnkey solution replacing competitor discontinued power supply

- Fully tested by TDK-Lambda to increase customer productivity

TDK-Lambda Value is enhanced

when our engineering team is seen as an extension of your engineering team for Power

Leverage our expertise early in the design cycle

Value AddScalable Power System for Interactive Video Wall Display

- Market Segment: Information Communication Technology (ICT)

- Application: Interactive Video Wall Display

- Standard Power Platform: SWS1000L (AC/DC)

Key Features:

- Three SWS1000L units connected in parallel

- Full Turnkey solution to support 19” rack mount application

- N+1 Power Redundancy

- Low audible noise

TDK-Lambda Value is enhanced

when our engineering team is seen as an extension of your engineering team for Power

Leverage our expertise early in the design cycle

Value Add45,000 Watt Non-Isolated Solution with 3-phase Input

- Market Segment: Semi-Fab

- Application: Semiconductor Testing

- Standard Power Platform: TPS4000 (AC/DC)

Key Features:

- Parallel 10 PFC modules in 2U 19" Rack

- I2C Communication

- Up to 98% efficiency

TDK-Lambda Value is enhanced

when our engineering team is seen as an extension of your engineering team for Power

Leverage our expertise early in the design cycle

Value Add1,500 Watt Solution with Programmable Constant Current Mode

- Market Segment: Industrial

- Application: Water Purification System

- Standard Power Platform: HWS1500 (AC/DC)

Key Features:

- Add Programmable Constant Current feature to standard product

- LED Indicators and Relay Contacts

TDK-Lambda Value is enhanced

when our engineering team is seen as an extension of your engineering team for Power

Leverage our expertise early in the design cycle

Value AddCustomized Rack Configuration with 3-phase Input

- Market Segment: Industrial

- Application: Web Press Printer

- Standard Power Platform: TPS3000-48 (AC/DC)

Key Features:

- Support customer unique mounting requirement

- Up to 8 racks connected in parallel

TDK-Lambda Value is enhanced

when our engineering team is seen as an extension of your engineering team for Power

Leverage our expertise early in the design cycle

Value AddSingle Phase Input – Motion Control Power System

- Market Segment: Semi-Fab

- Application: Wafer Inspection System

- Standard Power Platform: RFE1600-36 (AC/DC)

Key Features:

- Multiple outputs (+/- 72VDC & 36VDC)

- Using standard TDK-Lambda products for quick turnaround

- Lower development risk with TDK-Lambda standard products

TDK-Lambda Value is enhanced

when our engineering team is seen as an extension of your engineering team for Power

Leverage our expertise early in the design cycle

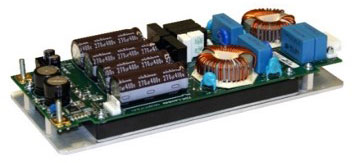

Brick-on-BoardDual input (AC & DC), 260W, 52V Single Output

- Market Segment: Defense

- Application: Outdoor Radio Communication System

- Standard Power Platform: PFE300 (AC/DC) + PX (DC/DC)

Key Features:

- Using standard TDK-Lambda products for quick turnaround

- Lower development risk with TDK-Lambda standard products

TDK-Lambda Value is enhanced

when our engineering team is seen as an extension of your engineering team for Power

Leverage our expertise early in the design cycle

Brick-on-BoardLow Profile 1,000 Watt Turnkey Assembly

- Market Segment: ICT

- Application: Distributed Antenna System (DAS)

- Standard Power Platform: PFE1000F (AC/DC)

Key Features:

- Conduction Cooled

- Using standard TDK-Lambda products for quick turnaround

- Low profile and compact size

TDK-Lambda Value is enhanced

when our engineering team is seen as an extension of your engineering team for Power

Leverage our expertise early in the design cycle

Value AddCustomized Rack Configuration with 3-phase Input

- Market Segment: Communication

- Application: Broadcasting

- Standard Power Platform: PFE500 (AC/DC)

Key Features:

- 52Vdc @ 500W

- Designed to interface with existing Network Interface Unit

- Fully tested by TDK-Lambda to increase customer productivity

TDK-Lambda Value is enhanced

when our engineering team is seen as an extension of your engineering team for Power

Leverage our expertise early in the design cycle

Brick-on-Board1,500 Watt Turnkey Assembly – Supports Water Cooling

- Market Segment: Industrial

- Application: DC/DC Hybrid Electric Vehicle

- Standard Power Platform: PAF700F48-12 (DC/DC)

Key Features:

- 240 VDC – 390 VDC input, 15 Volt output

- Conduction cooled solution that mounts to water cooled plate

TDK-Lambda Value is enhanced

when our engineering team is seen as an extension of your engineering team for Power

Leverage our expertise early in the design cycle

Brick-on-BoardConduction Cooled for Fully Sealed Outdoor Applications

- Market Segment: LED Application & Signage

- Application: Outdoor Ruggedized Display

- Standard Power Platform: PFE1000F (AC/DC)

Key Features:

- Conduction Cooled for fan-less operation

- Conformal Coated for extra protection

- N+1 Power Redundancy for improved reliability

- Turnkey solution, increased customer productivity

TDK-Lambda Value is enhanced

when our engineering team is seen as an extension of your engineering team for Power

Leverage our expertise early in the design cycle

Value Add DC/DC BoardMultiple Output Configurations – Flexible, Fast Time to Market

- Configure your Value Add DC/DC board with our standard DC-DC converters like the i6A4W (SIP) and i3A series; see example

- CCG30 (DC/DC) and i6A4W (DIP) can also be used to configure your Value Add DC/DC board

- Pair your Value Add DC/DC board with a single output AC/DC converter like the CUS350M (see example below)

Explore our standard AC/DC and DC/DC products to configure your own unique solution!

Contact our sales team for more information

Collaborative Design Approach

- TDK-Lambda's Engineering team is an extension of our customers' Engineering teams

- Global field engineering support for you

- Extensive Design Integration and Program Management Support

Global Manufacturing and Design Support

- Six Global ISO9001 and ISO14001 Engineering centers in Japan, China, Singapore, UK, Israel and USA

- Manufacturing locations in Japan, China, Europe, Asia and the Americas

Breadth of Product Strength

- More than 6,000 fully qualified standard models to be used as building blocks

- AC-DC, DC-DC, High Voltage and Programmable AC-DC, DC-DC power supplies

- Additional products include EMC and EMI noise filters

70+ Years of Knowledge and Expertise

- Leaders in the development and application of advanced technologies

- More than 700 patents

- Integrating latest components (GaN semiconductors) and design techniques

Legendary Quality

- Professional Failure Analysis

- Process Capability Index (Cp, CpK Requirements)

- Advanced Statistical Controls

- Industry-leading Warranties

- Rigid component Approved Vendor List (AVL) selection and management

Reliability by Design

- Detailed EVT/DVT test plans

- Product qualification consistent with IPC9592B guidelines

(HALT, HASS, TCT, THB, shock and vibration and demonstrated life testing) - Reliability Models (MTBF, Bel-core, Mil-Std-217)

- Component Stress Analysis

Accumulating more than 70 years of know-how and history, TDK-Lambda is a world class leader in the design and manufacture of power supplies for the Industrial, Medical, Semiconductor, Communications and Test & Measurement market.

#1 Global Supplier for Industrial and Medical Power Supplies (Source: IHS Market)