- HOME

- Applications

- Semi Fab

Almost everything we touch on a daily basis has an Integrated Circuit (IC). These sophisticated ICs are hidden from sight, but their functions are vitally significant to our daily lives. ICs also enable advances in critical applications like healthcare, clean energy and countless others.

Hundreds of processes are required to produce a semiconductor wafer. Many different types of machines are required during fabrication, each with a different power requirement. Some need very little power, such as the tracking of transfer systems that move wafers from one location to another. Other processes demand substantial power, especially during high volume testing.

Semiconductor fabrication equipment has to operate flawlessly 24 hours a day for maximum production yields

Technology is an integral part of our lives. If the production of semiconductor devices is sustained, then we can continue to flourish through technology. But semiconductor fabrication equipment is at risk because production lines can cease to work without Clean and Stable Power.

Prevent line down situations for your equipment by utilizing Standard and/or Value Add Solutions designed with TDK-Lambda’s 71+ years as a global leader in Industrial power solutions.

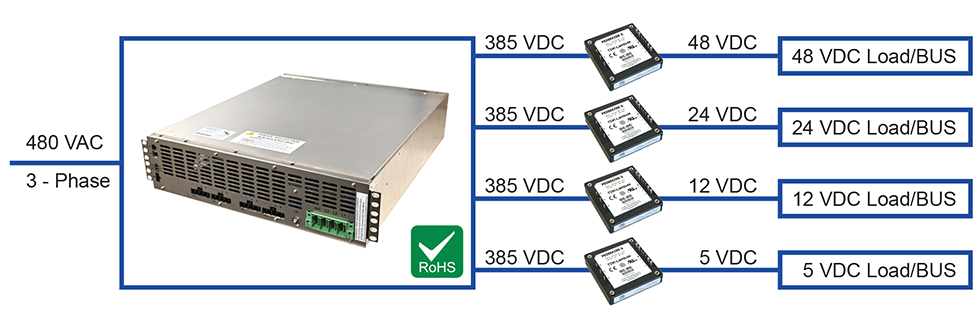

Distributed Power Architecture

What is Distributed Power Architecture (DPA)?

A power system that uses AC-DC or DC-DC front-end power supplies to convert AC utility voltage into a DC bus voltage, which is then converted by the DC-DC converters to the point of load voltage.

Typical DPA consists of the following

•AC-DC front-end (bulk power) with a universal input to create a DC bus voltage

•DC-DC Stage - Combination of isolated converts, bus converters, non-isolated converters (POLs), VRMs or integrated/discrete semiconductor devices

What are the advantages of using a High-Voltage DPA?

•Higher efficiency compared to low voltage DPA, especially with higher power requirements

•High-Voltage DC Bus (385Vdc) is generated to lower the I2R losses in the transmission to the DC-DC converters

•Lowers the maximum current and reduces the wire size to save cost

•Eliminates power conversion stages

•Ideal when loads are located at a distance from each other

•TPF45000 Non-Isolated AC/DC Power Supply

•Up to 45kW output, 10 each 4,500 Watt modules

•Scalable output from 4,500 to 45,000 Watts

•Can drive many isolated DC/DC Converters

Multiple outputs using the

PH-A Isolated DC/DC Converters

from 50-1200 Watts, 3.3V - 48V outputs

UL 508

Challenges

UL508 is the safety standard for industrial control equipment rated 1500V or less. Power supplies are thermally tested to ensure they will operate safely in enclosed cabinets or as stand-alones. Terminations to the products have to be designed to be field wired, often with bare wire connections.

Our Solutions

Our supplies with 508 certification are UL "listed" rather than "recognized". This allows the product to be used as a stand-alone device without the need to be fitted into an enclosure. In addition to our extensive DIN rail mount power supplies, many of our metal cased industrial products are UL 508 certified.

Peak Power

Challenges

Peak current demands from the power supply exist during start-up and during processes. These peaks can usually be attributed to solenoid relays, pumps and motor controllers. Costly mistakes in power supply selection can be made by not taking into account the peak current demands. Repetitive peak loading on a power supply that is not designed for the task can lead to early failures.

Our Solutions

Selecting a power supply capable of continuous power at the peak load may may result in a greater cost and larger product size.

We offer products that support peak current demands and are capable of doing so reliably.

Sequential Power-Up

Challenges

Sequential start up may be a requirement for automated systems. In most cases, the user requires logic/control circuits to be powered first before subsequent circuits driving a motor, laser or other devices.

Our Solutions

We offer multiple-output products with individual output enable, inhibit, and DC good signaling that supports safe and reliable sequencing during start up.

440 vs. 208VAC Input

Challenges

High power applications require three-phase Delta or Wye configurations at voltages of 400, 440 and 480VAC. Typically, a large and expensive step-down transformer is used to provide a lower input line voltage (208/240VAC) to a traditional power supply.

Our Solutions

We offers products that operate on 3-phase, higher voltage inputs, reducing cost by eliminating the need for a step-down transformer.

SEMI F47 Line Dips

Challenges

SEMI F47 is the standard used by the semiconductor fabrication industry. It dictates the performance of a power supply during AC line outages caused by lightning. This avoids equipment shutting down during time-critical wafer fabrication resulting in the loss of work in progress.

Our Solutions

The vast majority of our products are designed to perform continuously during these AC line dips and disruptions.

Why TDK-Lambda?

Explore our suggested solutions for Semiconductor equipment

TPF Series - 4500W to 45,000W - Single Output AC-DC

- ♦ Modular supply with 10 4,500W modules

- ♦ 400/440/480 VAC (Nom.) 3Ph Delta or Wye

- ♦ PMBus™ and USB Interfaces

- ♦ 98% Efficiency

- ♦ -20°C (start up) to +50°C operation

- ♦ Less than 30kg Weight

PH-A Series - 50W to 1200W - Single Output DC-DC

- ♦ Quarter, Half & Full Brick Sizes

- ♦ 200-425 Vdc Input

- ♦ 3.3, 5, 12, 24, 28, 48 Vdc Outputs

- ♦ 3000 Vac Isolation

- ♦ -40 to 100 °C Baseplate Temperature

- ♦ IEC/EN62477-1 OVCIII (300-600W)

- ♦ Parallel Operation (1200W)

TPS Series - 2040W to 4080W - Single Output AC-DC

- ♦ 400/440/480 VAC (Nom.) 3Ph Delta or Wye

- ♦ Fully Regulated, Wide Range Adj. Output

- ♦ Voltage and Current Programming

- ♦ -40°C (start up) to +70°C operation

- ♦ Up to 92% Efficient

- ♦ PMBus™ Communication

- ♦ Built-in ORing FET for parallel operation

HWS-G Series - 3000W - Single Output AC-DC

- ♦ 3000W programmable power supplies

- ♦ Single or three phase inputs

- ♦ 24, 48, 60, 130 Vdc Outputs

- Serial or Analog Programming (CV/CC)

- ♦ High Efficiency

- ♦ IEC/EN62477-1 OVC III

- ♦ Industrial

CUS350MP Series - 350W to 1000W - Single Output AC-DC

- ♦ 350W (1000W Peak) Convection Cooled

- ♦ 1000W Peak with Forced Air

- ♦ Medical Certifications (2xMOPP)

- ♦ Class B Conducted and Radiated EMI

- ♦ 5V 0.3A standby voltage, Remote on/off

- ♦ Compact size (88 x 183 x 44mm)

- ♦ Five year warranty

CUS800M-1000M Series - 680W to 1000W - Single Output AC-DC

- ♦ Low Cost

- ♦ Variable speed low noise fan

- ♦ Medical Certifications (2xMOPP)

- ♦ Class B Conducted and Radiated EMI

- ♦ Compact 3.3 x 6.7 x 1.67" size

- ♦ <0.250mA Leakage Current

GENESYS+™ Rack DC Series - 30kW to 90kW - Single Output (Rack DC System) Programmable DC

- ♦ DC Power Systems: 30kW, 45kW, 60kW and 90kW

- ♦ VO(rated) up to 1500V; IO(rated) up to 4500A

- ♦ CV, CC and CP Limit Operating Modes

- ♦ Advanced Features Built-In

- ♦ Built-In LAN, USB, RS-232/485 and Isolated 5V/10V

- ♦ Optional IEEE, ECAT, Modbus-TCP, Isolated 4-20mA

- ♦ Safety Agency Approvals / 5 Year Warranty

Genesys™ Series - 600W to 15,000W - Single Output Programmable DC

- ♦ Pout(rated) from 750W (1U) to 15kW (3U)

- ♦ VO(rated) up to 1.5kV; IO(rated) up to 1000A

- ♦ Built-In Safety and Protection Features

- ♦ Standard RS-232 / RS-485 / Remote Analog

- ♦ Optional LAN (LXI 1.5), USB (2.0), IEEE (GPIB)

- ♦ Optional Isolated 5/10V or 4-20mA Interfaces

- ♦ Safety Agency Approvals / 5 Year Warranty

GENESYS+™ Series - 1000W to 15,600W - Single Output Programmable DC

- ♦ Pout(rated) from 1kW (1U) to 15kW (3U)

- ♦ VO(rated) up to 1500V; IO(rated) up to 1500A

- ♦ Advanced Features Built-In

- ♦ Scalable Power Systems up to 60kW

- ♦ Built-In LAN, USB, RS-232/485 and Isolated 5V/10V

- ♦ Optional IEEE, ECAT, Modbus-TCP, Isolated 4-20mA

- ♦ Safety Agency Approvals / 5 Year Warranty

ZBM Series – Buffer Module (Accessory)

- ♦ Provides 380ms Additional Hold-Up Time at Max Buffer Power

- ♦ Utilizes Electrolytic Capacitors to Store Energy

- ♦ Parallel Capable

- ♦ Output Remote On/Off Function

- ♦ 5 Year Warranty

HFE Series - 1584W to 2500W - Single Output AC-DC

- ♦ 1U rackmount containing up to 5 units

- ♦ Up to 29.2W/in³ power density

- ♦ Internal ORing MOSFET & Current Share

- ♦ High Efficiency

- ♦ Up to 9,500W in 1U rack

- ♦ PMBus™(I2C) and LAN options

RFE Series - 1000W to 2500W - Single Output AC-DC

- ♦ 1U High

- ♦ Internal ORing FETs and Current Share

- ♦ High Efficiency

- ♦ I2C, PMBus™ Communication option