Tuesday, September 3, 2024

Nanocrystalline soft magnetic materials offer a number of advantages: A higher permeability in the lower frequency band (tens of kHz) for better magnetic performance and damping, lower core losses to reduce heating and an improved thermal stability for operation over wider temperature ranges when compared to traditional ferrite materials.

The Power Supply Manufacturers Association held an informative online seminar in July on the use of nanocrystalline soft magnetic materials. These core types are well suited for use in common mode inductors for EMC (Electromagnetic compatibility) filtering applications. The growing e-mobility industry, in particular the electric vehicle charging station sector is a target market for this material.

How are they manufactured? A traditional ferrite core uses a pressed powder mixture which is heated to an elevated temperature using a kiln (~1000oC), followed by a machining process.

A nanocrystalline core uses a process similar to that of an amorphous core. The raw material is heated to over 1000oC and sprayed onto a spinning water cooled wheel to rapidly lower its temperature in a fraction of a second.

On the downside, nanocrystalline cores are more expensive and have inferior magnetic saturation properties compared to amorphous cores. Excellent core saturation characteristics are essential for pulse attenuation.

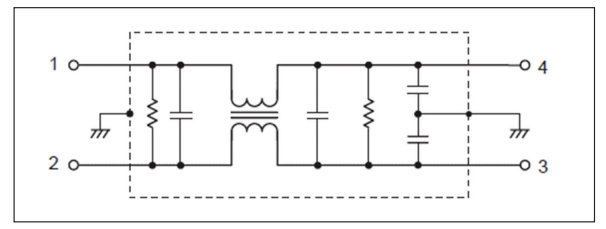

TDK-Lambda has EMC filters using all these core materials and it is interesting to compare their performance for a single and two stage single-phase 20A 250Vac filters (See Figure 1).

Figure 1: Typical schematic for a single stage filter (top) and a two stage filter (bottom)

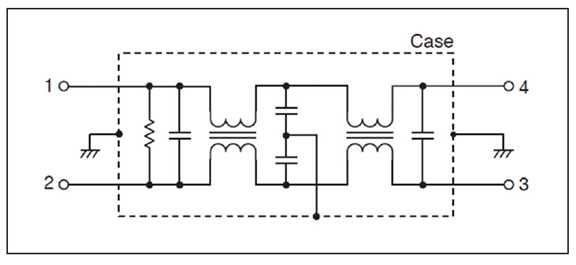

Figure 2: RSKN filter

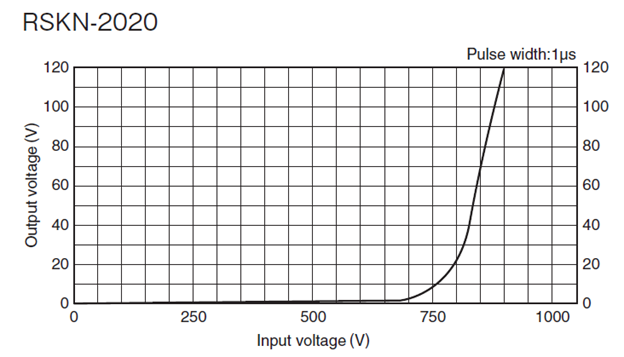

The RSKN-2020 (Figure 2) is a wideband two stage filter using nanocrystalline cores.

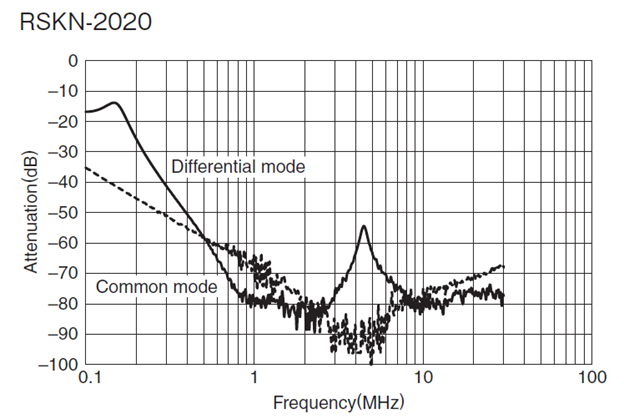

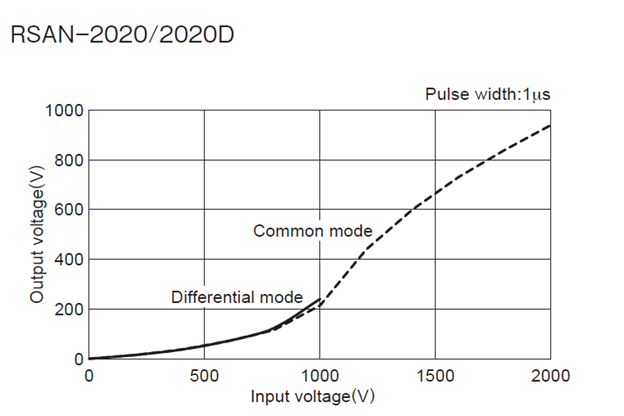

The RSAN-2020 (Figure 3) is a single stage filter with an amorphous core

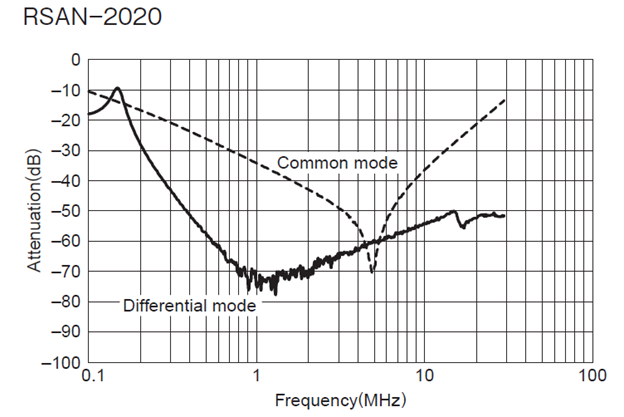

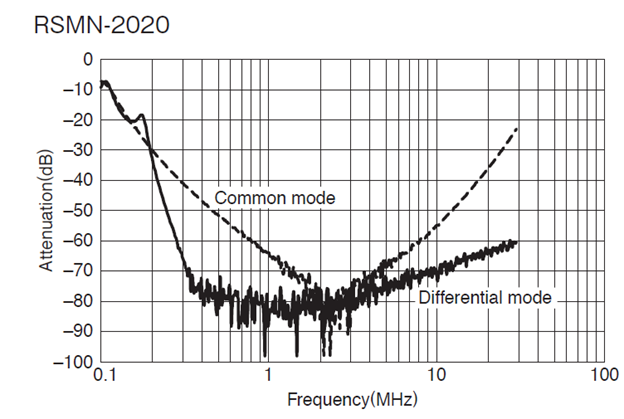

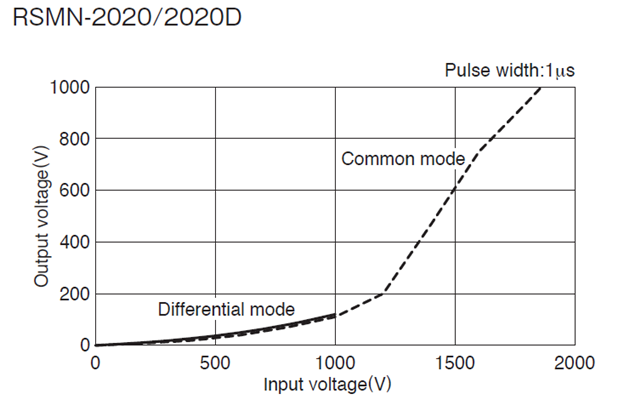

The RSMN-2020 (Figure 4) is a two stage filter with ferrite and amorphous cores

RSKN Attenuation vs. Frequency characteristics

RSAN Attenuation vs. Frequency characteristics

RSMN Attenuation vs. Frequency characteristics

Note that the RSKN filter with nanocrystalline core technology has significantly better attenuation performance.

RSKN Pulse Attenuation characteristics

RSAN2020 Pulse Attenuation characteristics

RSMN Pulse Attenuation characteristics

Summary

The RSKN filter has very good attenuation in the midband frequency range but are not as good with input pulses. As expected, the single stage RSAN filter has good attenuation for high voltage pulses with the amorphous cores. The two stage RSMN filter perform wells in both categories.

When selecting an EMC filter it is advisable to review the manufacturer’s data and use a filter based on your application needs. For a noisy industrial environment, it is certainly worth considering a filter that can reduce the amplitude of incoming pulses and potentially avoid equipment damage.

For more information visit TDK-Lambda’s EMI solutions webpage

Power Guy