Technical Article – Efficiency Trends in Power Conversion

Thursday, April 14, 2022

April 2022

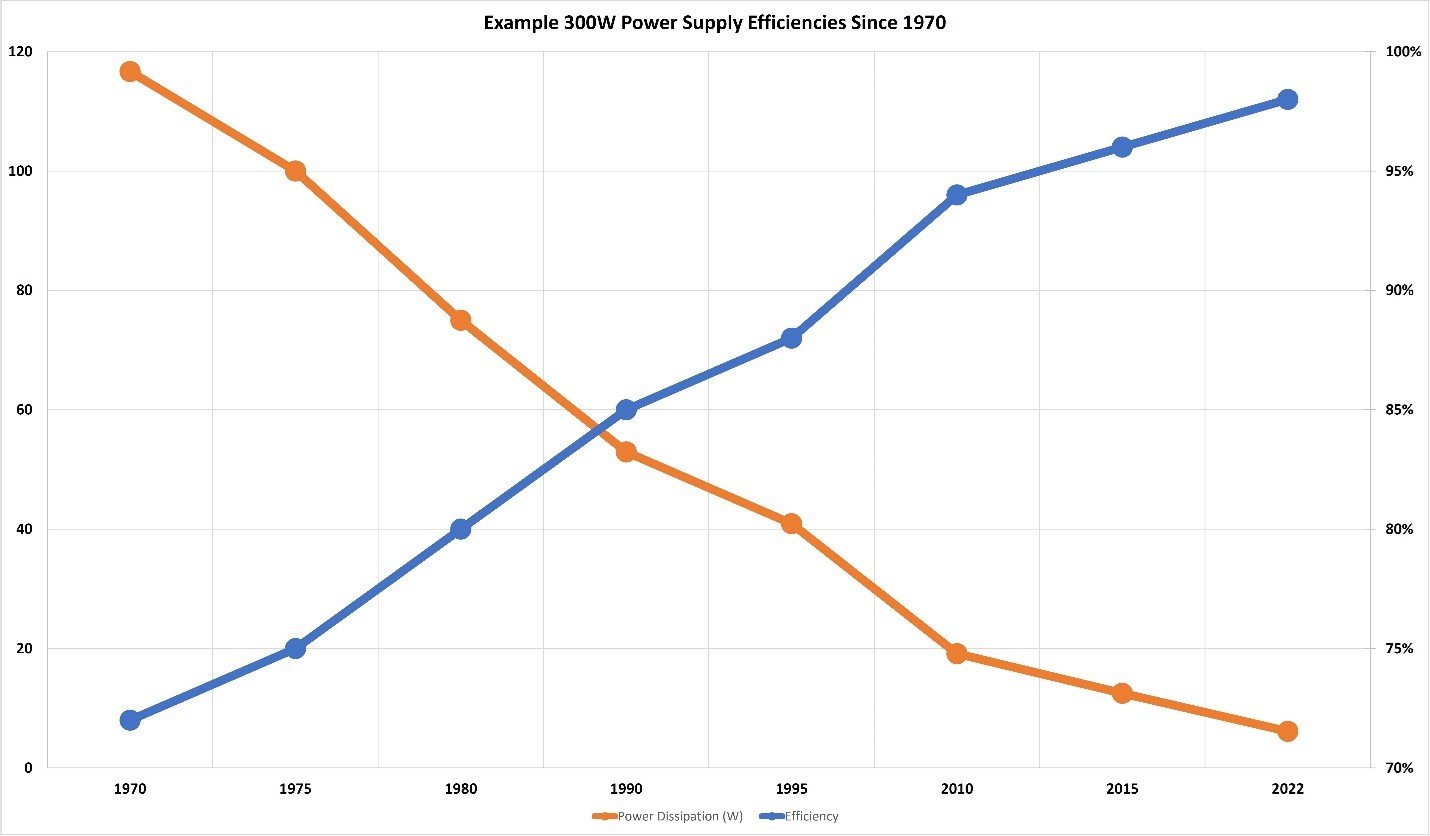

We’ve come a long way from vacuum tubes and linear series pass power supplies. Driven dominantly by the ever-growing demand for feature density (the aesthetic and logistical benefits of fitting more functionality and capability into smaller packages), we’ve seen average electrical power conversion efficiencies soar from circa seventy percent to nearly one hundred percent over the past five decades, as depicted in the chart below.

These improvements enable the development of smaller, lighter products with reduced operating costs, and are critical for resource conservation and energy sustainability. But the pursuit for greater conversion efficiencies is one with diminishing returns. Each percentage point is exponential more difficult to achieve. Let’s take a closer look at how we got to where we are today, with power converters exhibiting peak efficiencies of more than 97%, and where we are headed tomorrow. How close can we come to a lossless power converter?

CONVERSION LOSS MECHANISMS SUMMARIZED

To appreciate the engineering challenges involved in improving power supply conversion efficiency, it is important to first understand the major loss mechanisms. In general, the efficiency of a system is defined as the ratio of the amount of power leaving the system to the amount of power entering the system. The difference between the input and output power quantities is the loss, or how much power is consumed by the system and dissipated as heat. Power is dissipated anytime electrical current flows in a material according to equation below.

where I represents the current in amperes and Reff represents the materials effective resistance. There are several reasons current may flow through a real effective resistance inside of a power converter, and we can classify these into a few major categories.

Semiconductor Losses: Modern power converters utilize semiconductors in both the control and power stages. These semiconductors pass nearly zero current in the off state (no loss) and dissipate power as heat according [equation 1] both in the on-state (according to the effective on state resistance, Ron) and in the transitional period between the off and the on states where the effective resistance decreases from nearly infinite to Ron. The losses can be mitigated by reducing Ron, reducing the amount of time spent in the transitional state (faster switches), and by transitioning less often (lower frequency operation or burst mode operation).

Rectifiers make significant contributions to overall semi-conductor losses as well. These elements dissipate power in the on state proportional to their forward voltage, and during the reverse recovery period when charge carriers are swept out of the depletion region. There is a physical limit to how low a PN junction forward voltage can be that cannot be mitigated with geometric manipulation (larger packages or parallel elements). These losses are particularly appreciable in high current, low voltage circuits (like the secondary of a low voltage DC supply). One of the best mitigation tactics is to deploy “ideal rectifiers”, which are just transistors with control circuitry designed to emulate a diode. This practice is commonly referred to as synchronous rectification.

Magnetics Losses: We rely heavily on magnetic structures for filtering, and often for providing galvanic isolation between the mains connected primary and the user facing secondary. Inductors and transformers can be exceptionally lossy. Relatively great lengths of conducting material are needed to achieve required geometries, and the winding resistance is directly proportional to this conductor length. These conduction losses are augmented by the skin effect, which forces charge carries to flow along the surface of the windings with an increasingly less uniform distribution as frequencies rise.

Magnetic core materials also have real resistances, and as the magnetic field within them alternates, electrical potential is induced across this real impedance, and a current (known as an eddy current) begins to flow and dissipate power as heat. Magnetic materials in alternating fields also exhibit hysteresis losses. A non-zero amount of energy is required to reorient the atoms within the core each time the field changes direction. Losses can be mitigated by using lower impedance windings (larger cross-sectional areas, with maximized surface area’s), and by deploying core materials and constructions that offer low magnetic reluctance and simultaneously high effective electrical resistance. Using laminated cores or powder cores can further reduce losses by splitting the induced potential up across smaller segments of Ohmic material. Hysteresis losses are directly proportional to switching frequency. Fewer transitions result in lower losses, but this of course is not conducive with reducing the size of the largest and heaviest components in the device.

Miscellaneous Losses: Energy is required to carry out various other functions within the power converter such as turn switches on and off, measure voltages and currents, and process those measurements to make informed decisions to regulate the output characteristic. Switching power converters are also quite noisy. A lot of filtering is required to comply with RF emissions limits and to allow for clean, low-ripple DC voltage at the load. While these filters are composed of reactive elements, no reactive element is ideal, and parasitic resistances in capacitors and inductors burn off power as energy is exchanged between them.

IMPROVEMENTS OVER TIME

As we take a walk from the lossy linear regulators of the early 20th century that regulated load voltage by intentionally wasting energy, to modern resonant switching converters deploying ultra-low loss semi-conductors, magnetics, and clever control schemes, the improvements to conversion efficiency have been truly incremental. Power supply designers have been chipping away at the dominant loss mechanisms through a combination of discrete improvements in topological selection, control technique, and component selection.

Topologies: Switch mode power conversion, the practice of connecting the source to the load for discrete chunks of time (through a low pass filter) rather than simply burning off the difference between the two as heat, first garnished measurable attention from the engineering community in the late 1950’s. The theoretical concept had been around with little practical applicability for roughly 30 years prior. Switch mode opened the flood gates for a large family of conversion topologies that would grow ever more efficient with each decade.

Resonant topologies, like the LLC resonant converter have gained increased popularity in recent years as they allow for soft switching (making semiconductor state transitions when either the voltage across or current through the element is naturally zero). With Zero Voltage Switching (ZVS) and Zero Current Switching (ZCS), semiconductor switching losses are almost entirely mitigated, allowing switching frequencies to rise and converters to shrink. Design and analysis of these highly efficient topologies is a good deal more complex than with traditional switch mode topologies like the forward converter or the flyback. This is a contributing factor to the seemingly late widespread adoption. The first resonant converter designs date back to the late 1980’s. It wasn’t until the growing demand for higher power densities met the physical limits of hard switching topologies that these more complex topologies picked up traction.

Control: The growing off-the-shelf selection of energy conscious control IC’s continues to fuel the development of low cost, high efficiency power supply families. One of the most challenging areas to improve converter efficiency is during light load operation where the delivered power is on the same order of magnitude as the quiescent consumption. The only way to drive efficiencies up under these conditions is to further reduce the quiescent draw. Low power controllers with intelligent light-load switching schemes like frequency tapering and/or cycle skipping become imperative.

Customized digital control (via embedded microprocessors) is becoming more ubiquitous, especially in higher power product lines. It is becoming increasingly common to see software engineers on power electronics design teams. Precisely tailored control gives power supply designers an extra degree of freedom as they strive to maximize energy savings.

Components: Once we’ve optimized our topology and control scheme, our converters are only as efficient as their constituents. Recently, there have been great strides in power conversion efficiency riding on the coattails of wide band gap (WBG) semiconductor development. With materials like gallium nitride and silicon carbide, semi-conductor manufacturers can achieve miniscule on-state impedances and lightning fast state transitions. Improvements in manufacturing processes have resulted in wider availability of cost-effective low loss magnetics deploying low impedance winding geometries such as Litz wire or flat windings. Some marginal energy savings can be realized by taking care to seek low ESR capacitors in high-ripple circuits.

The Future of Power Supply Efficiency

By deploying the latest topologies, control techniques, and components, the power supplies of today can quite readily achieve average efficiencies north of 95% As the world continues to seek smaller, lighter devices, efficiencies will need to continue to rise in support. While achieving 100% efficiency is impractical, if not arguably theoretically impossible, power supply designers continue to push the envelope. Power supply products like TDK-Lambda’s new CUS600M Series (up to 96% efficient), TPF45KW (up to 98% efficient), and I-Series DC/DC converters (up to 98% efficient) exemplify what is possible with modern components and a design team dedicated to excellence in energy efficiency.

Downloads

• Efficiency Trends in Power Conversion (pdf)